Machines

Packaging lines

Contact us

Cindy

Fiona

Tel:0086-136 8527 0809

E-mail:fiona@ztpack.net

Add: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

4L -10L Automatic Net Weight Filling Machine

This is weighting type filling machine , widely use for oils / chemicals fill packing Filling System : Net weight Load Cell High Accuracy : 0.1% Suitable for : Lubricant Oil / Car Oil / Motor Oil / Coolant liquid / Engine Oil /Brake Oil ...Etc kinds Products Edible Cooking Oil Agrochemical / Fertilizer / Pesticide / chemical ... Capacity Speed : 6-10 Nozzles can be choosen

Product Description

Machine Name : 4L -10L Automatic Net Weight Filling Machine

Type: ZCJ-10

Brief Introduce :

The weighing filling machine is used for filling liquid in a range of 4 to 10kg.

It features a weight feedback system under each fill head to ensure the filling accuracy.

our 4L-10L Bucket Weighing Filling Machine, the perfect solution for filling liquid products such as oil or chemical substances. This state-of-the-art equipment is equipped with precision weighing sensors that ensure accurate filling dosage. With four or six filling heads, this machine can achieve a production output of 200-1000 buckets per hour, making it ideal for high-volume production environments.

Our bucket weighing filling machine is a reliable and efficient choice for businesses looking to streamline their filling process. Invest in our product today and experience the benefits of increased productivity and accuracy in your operations.

Suitable For Filling :

Edible oil

(Cooking Oil , sunflower oil , peanut oil , seasame oil ..., etc.);

Automatic packaging of Oil liquids.

Lubricant Oil :

Car Oil / Motor Oil / coolant liquid / engine oil / Lubricanting Oil kinds Products

Agrohchemicals :

Pesticide , fertilizer ,suspending agents, liquids, emulsifiable concentrates and water-soluble fertilizers, Acaricide,Fungicide,herbicide, EC ,SC , SL etc.);

Parameters :

Filling Range : 4L-10L

High Accuracy : 0.1 %

Filling System : Net Weight Load Cell Type

Capacity Speed : 6-10 Filling Nozzles Can Be Choose

Speed can be choosen : from 400BPH-1000BPH (basic on 10L )

Filling Line Machines included (can be choosen):

Depalletilizer --Filling Machine--Capping Machine -- Induction sealing machine -- Aluminum Foil detector and rejector --Labeling Machine --Cap & Label Check and Rejector --Date Printer -- Palletilizer-- Wrapping Machine

Detail Photos :

FEATURES

· The weighing filling machine is made of 304 stainless steel.

· The machine uses a PLC with touchscreen as its control system.

· The diving nozzle is designed to prevent bubble formation.

· Each fill head has a weight feedback system underneath to ensure the filling precision.

· The machine is easy to take apart and clean for routine maintenance.

· An alarm will sound in the event of machine failure.

· Flexible operation: suitable for filling bottles in a range of 4 to 10kg in capacity.

APPLICATION

The weighing filling machine is suitable for filling barrel products such as alcohol, cooking oil, lubricating oil, fertilizer agrochemicals and more.

How to choose automatic filling machine is big challenge for customers, If your are unsure how to choose a filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

Key Features:

Heavy duty stainless steel construction

-

Made by high quality 304 Stainless steel, it is durable.

-

316 stainless steel product contact parts is available for optional according to product features.

High speed & volume production

-

Quick-install connecting parts , it is easy to disassemble and clear machine.

-

Capacity to fill a variety of container types and sizes

High accuracy fill, less product waste

Automatic bottling index kit with bottle counter

Individual fill head control

Durable construction to ensure longer life of the machine

Real time net weight monitor

Drip pan

-

Liquid receive tray is available in case any dripping from filling nozzle.

-

Diving filling head is available for filling foamy liquid.

User friendly PLC controls with touch screen HMI

-

Easy change over to different size bottles.

Low maintenance & operating cost

Designed with common parts for easy & quick replacement

-

Easy to navigate user interface

-

Modular design makes it easy to integrate with other bottling machines

Adaptable to fit a variety of different container styles & sizes

No bottle, No filling

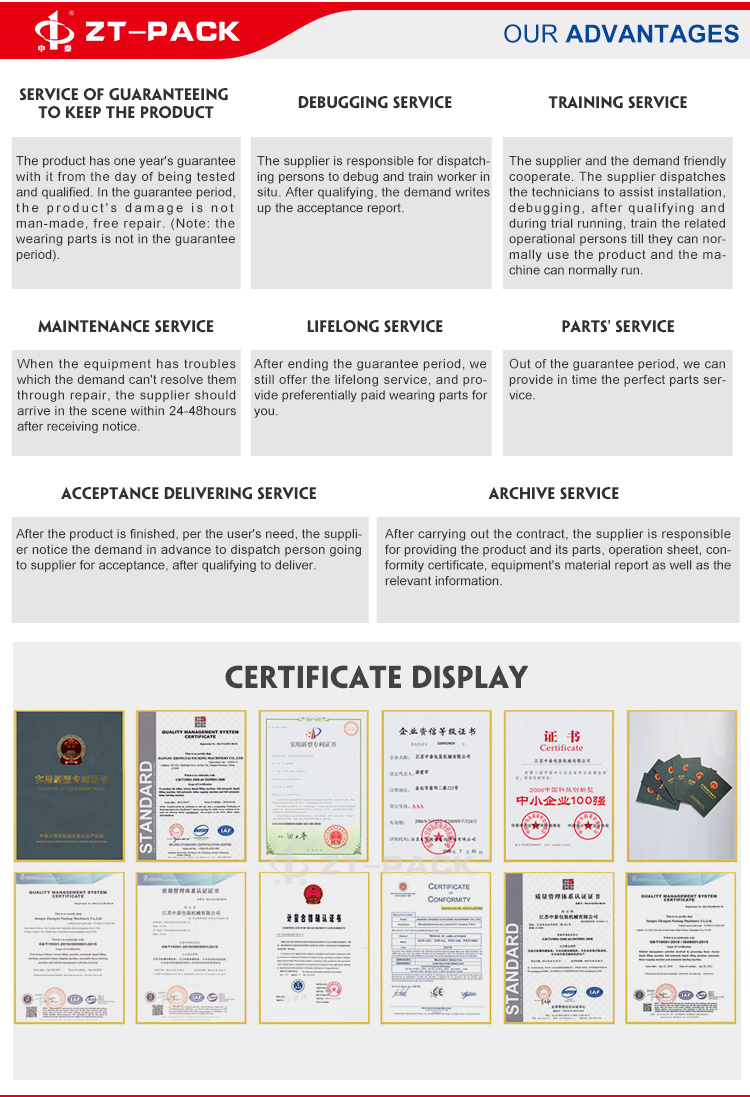

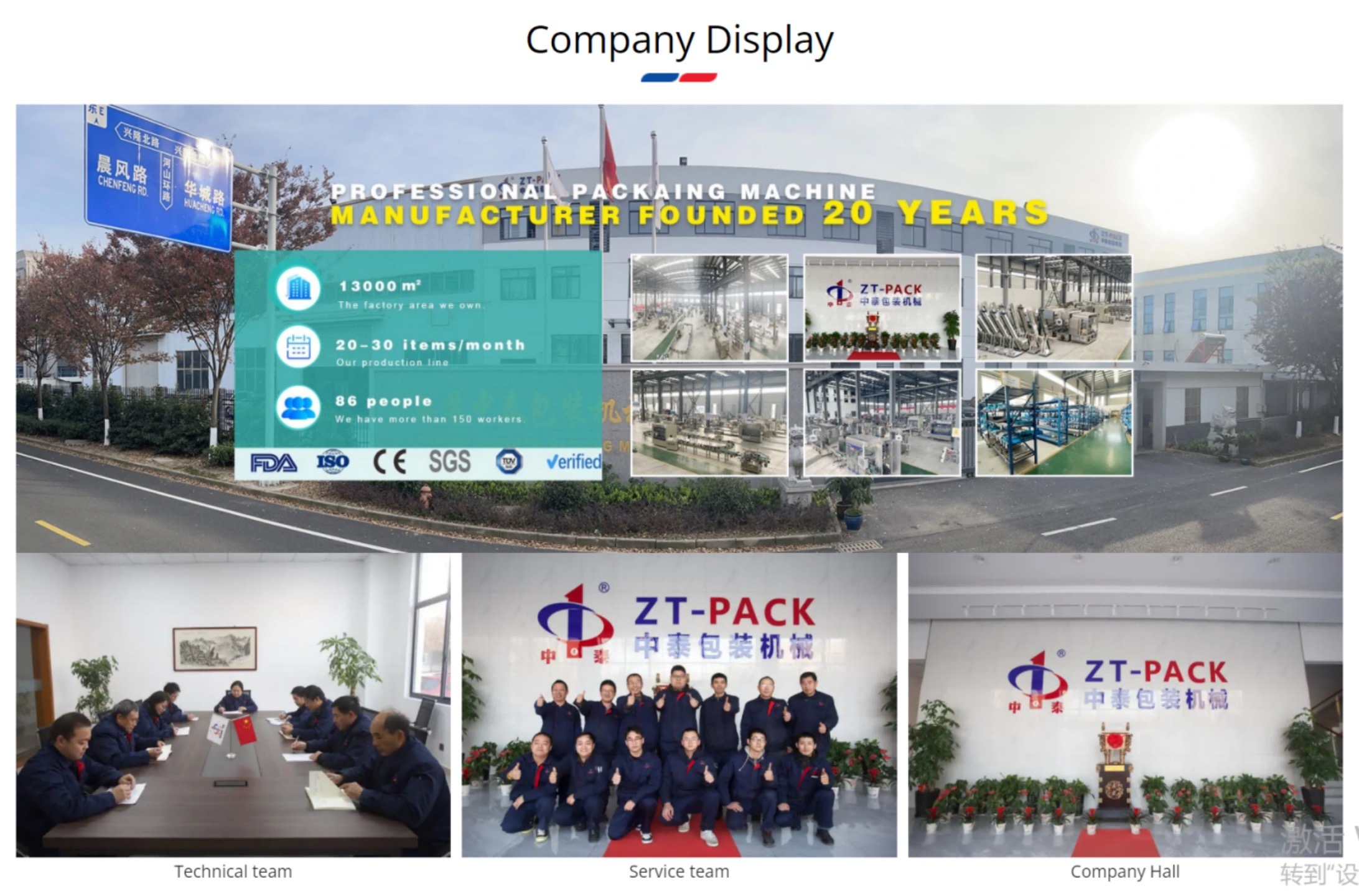

About us

Workshop :

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible

Contact Info

ADDRESS: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Questions? Contact Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible