Machines

Packaging lines

Contact us

Cindy

Fiona

Tel:0086-136 8527 0809

E-mail:fiona@ztpack.net

Add: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

0.5L-7L Flow Meter System Lubricant Oil Filling Machine

0.5L-7L Flow Meter System Lubricant Oil Filling Machine Suitable For Oils Filling with High Accuracy 0.2%. Have Different System Can Be Choosen: Flow Meter / Net Weight / Piston Suitable for fill : Lubricant Oil / Car Oil / Motor Oil / coolant liquid / engine oil / Lubricanting Oil kinds Products Filling Range : 50ml -1000ml 1L -5L 4L -20L 208L / 220L Speed can be choosen : from 1000BPH-6000BPH (basic on 1L )

Product Description

Machine Name : 0.5L-7L Flow Meter System Lubricant Oil Filling Machine

Type: ZCJ

Suitable for fill : Lubricant Oil / Car Oil / Motor Oil / coolant liquid / engine oil / Lubricanting Oil kinds Products

Filling Range : 0.5L-7L

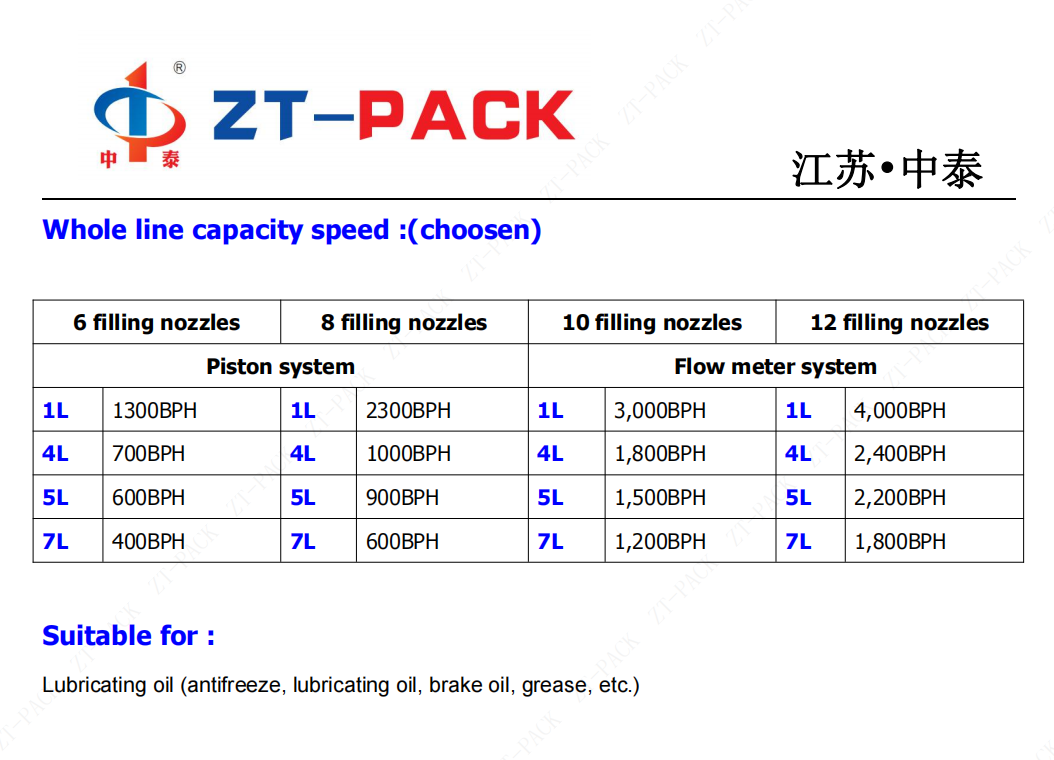

Speed can be choosen : from 1000BPH-6000BPH (basic on 1L )

Product description:

This type filling system is flow meter type which is the better ideal for oils filling packing

The principle of the elliptic gear flow meter is to measure the rotation of the elliptic gear by the pressure head of the measured medium.

The greater the viscosity of the medium, the smaller the leakage from the gear and the space gap, the greater the viscosity of the medium, the smaller the leakage error and the more favorable for the measurement.

The elliptical gear flow meter has high accuracy and is suitable for the measurement of the flow rate in the medium with high viscosity, especially for the filling of different labels and different viscosity.

The machine is made by in-line structure , filling head quantity can be custom-made according to different production capacity such as 4/ 6/ 8 /12 nozzles.

The filling volume is controlled by flow meter and gear pump, good filling accuracy and high filling speed.

Suitable for Fill :

Details pictures :

Advantage of Flow Meter System:

1: Quick Adjustment : The adjustment in dosage is convenience and quick, the volume only need to be set on the touch screen directly, considered that the vegetable oil is different in density in the different temperature, resulting in the volume setting different, we have added an automatic temperature-compensated system.

2: Filling Accuracy : instead of the traditional computing type of flow meter --through pulse generator, now promoted by our company, adopting rotary encode is more accurate.

3: Filling speed : instead of the traditional power delivery -- pressure artesian flow, our machine adopting frequency converter to adjust the speed of filling, the efficiency highly raised. The speed can be arbitrarily adjusted on panel. the adjustment of filling accuracy, promoted by our company, the weight of filling can be set on the touch screen.

4: It will not affected by the season, In summer and winter the oil all can be fill easily, not restricted by the viscosity of oil products, such as gear oil can also be easily filled. The more viscous material is, the more obvious the advantage of flow meter filling method is.

5: Easy Operate : The operation interface is simple, easy to learn and maintain, low requirements for field operators, use of startup and formula adjustment and one key solution

6: No wearing parts in the production process, mechanical transmission, The cost in use is lower.

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

Online message

Related Products

Online message

Contact Info

ADDRESS: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Questions? Contact Us