Machines

Packaging lines

Contact us

Cindy

Fiona

Tel:0086-136 8527 0809

E-mail:fiona@ztpack.net

Add: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

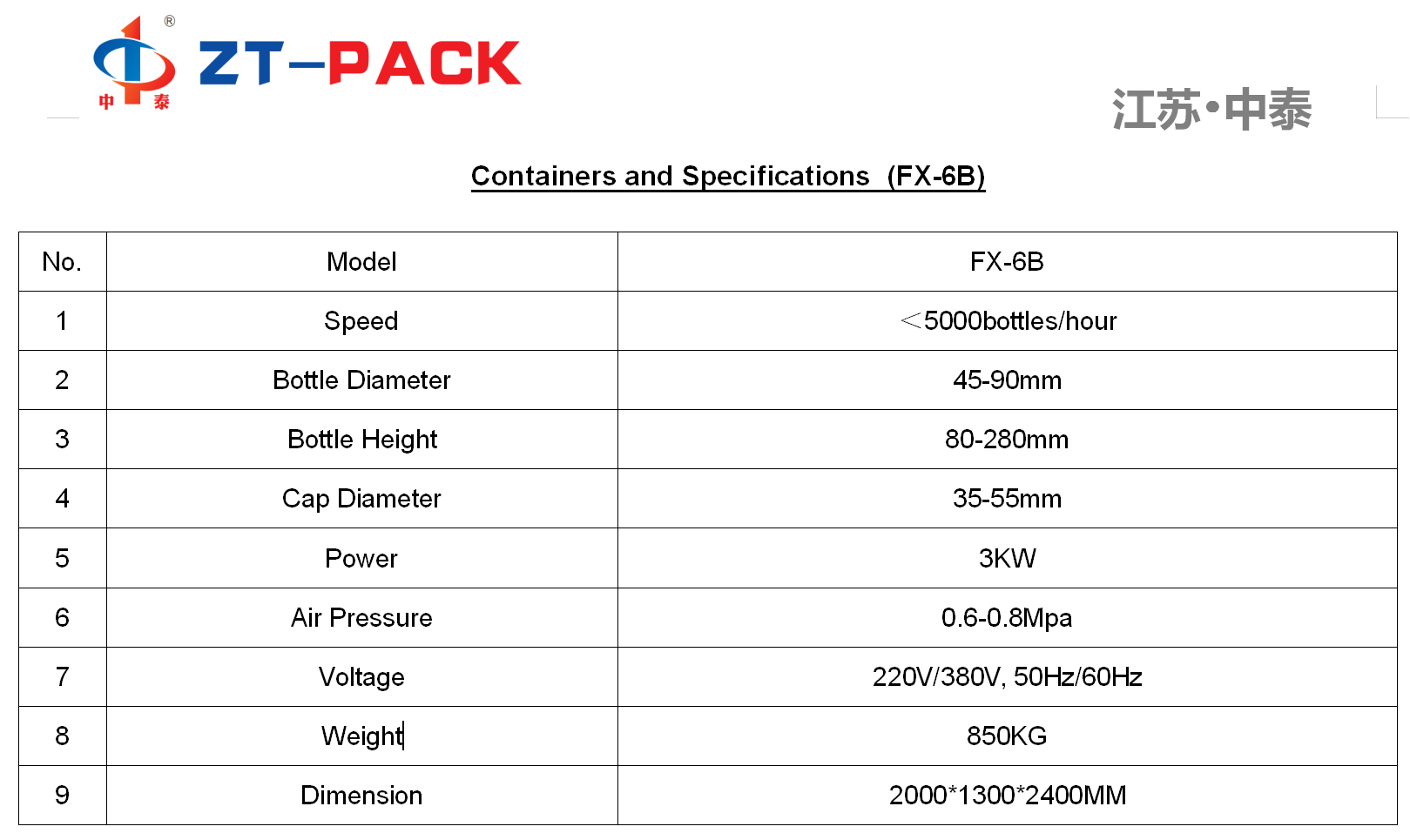

Rotary Capping Machine - Pick And Place Type FX-6B

Automatic rotary capping machines are designed to apply and rotate a pre-sorted cap on a container based on a predetermined applied torque. This provides the most accurate and uniform cap application to suit specific cap and container characteristics. used for closing plastics screw caps, especially for the caps which with lock ring. It is widely used in industries like foodstuff, pharmacy, daily chemical, cosmetic, fertilizer etc.

Product Description

Machine Name : Full Automatic Rotary Pick And Place Capping Machine

Type : FX-6B

Machine Description :

Pick and place type Rotary Capping Machine is used for closing plastics screw caps, especially for the caps which with lock ring. It is widely used in industries like foodstuff, pharmacy, daily chemical, cosmetic, fertilizer etc.

Automatic rotary cappers are designed to handle a wide range of caps including screw caps, press on caps, tamper proof caps, aerosol overcaps, inserts, ROPP caps, twist off caps on to plastic and glass containers. Rotary cappers have much higher speed capabilities than in-line capping machines.

PLC control system, rotary type structure, the machine is with function of automatic cap feeding ,loading and closing.

The containers are fed onto the rotary screw capper and are separated and positioned on individual capping stations. The caps are presorted and fed on the sliding table of the machine. The continuously rotating chucks are lowered over the cap to pick up and secure the caps, then apply the caps to the containers. When the preset applied torque value is achieved, the magnetic clutch disengages, the chuck releases the cap and the closed container is discharged from the machine.

With 6 mechanical hands ,the mode is suitable for multi-geometry containers,It bispatches caps at fast speed without any cap reversed . Supplying cap system and mechanical hands work together in phase . When the cap is tightened , bottle and cap stand still relatively ,and the clutch separates immediately so that able and not apt to be damaged .

Details Pictures :

Key Features:

Carbon steel base mounted on adjustable floor levellers for easy alignment

Bearing frame and all surface components manufactured in 304 stainless steel

Magnetic clutch capping heads for screw caps complete with pick & place cap system

Caps in chute photocell, machine will not work if there are no caps present on chute

Automatic cap feeder, chute and applicating head

Electrical socket for optional elevator feed

Safety guarding with interlock devices

Cap change parts complete set to run a different size cap(option)

Cap elevator to load the cap feeder automatically(option)

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible

Contact Info

ADDRESS: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Questions? Contact Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible