Machines

Packaging lines

Contact us

Cindy

Fiona

Tel:0086-136 8527 0809

E-mail:fiona@ztpack.net

Add: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Pre-Bag Filling Sealing Machine (up to 1kg)

Pre bag filling and sealing for bag with or without zipper filling range up to 1kg Great for packaging seasonings, flour, spices, chemicals, detergents and more.

Product Description

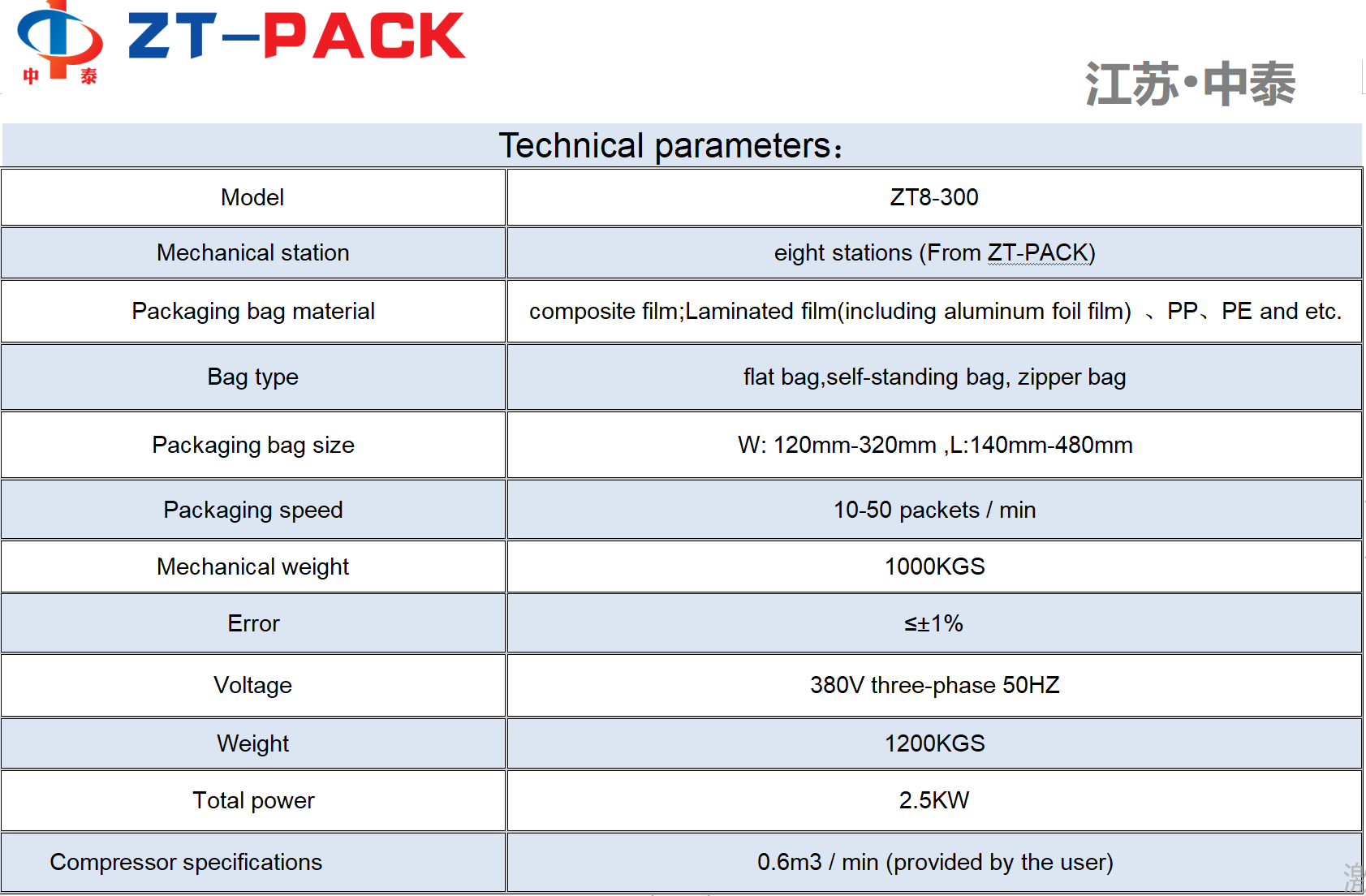

Machine Name : Full Automatic Pre-Bag Filling Sealing Machine (up to 1kg)

Type : ZT8-300

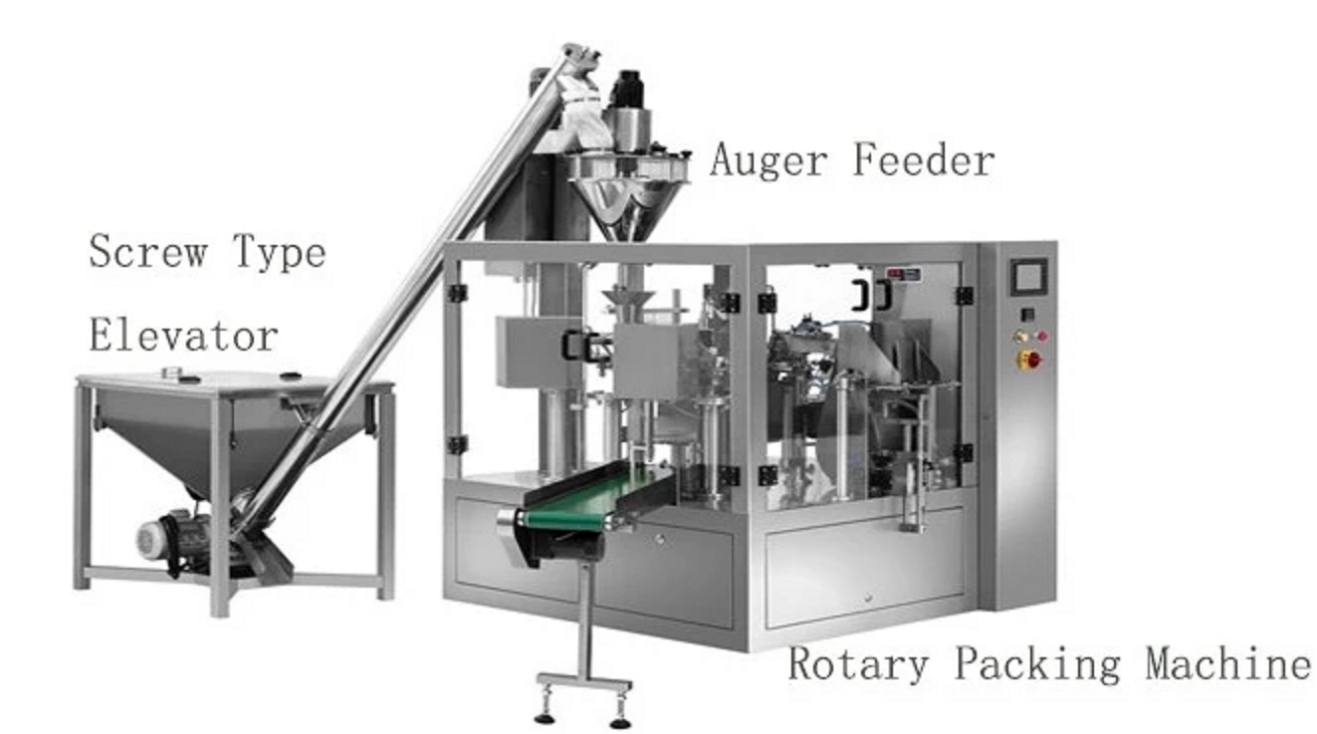

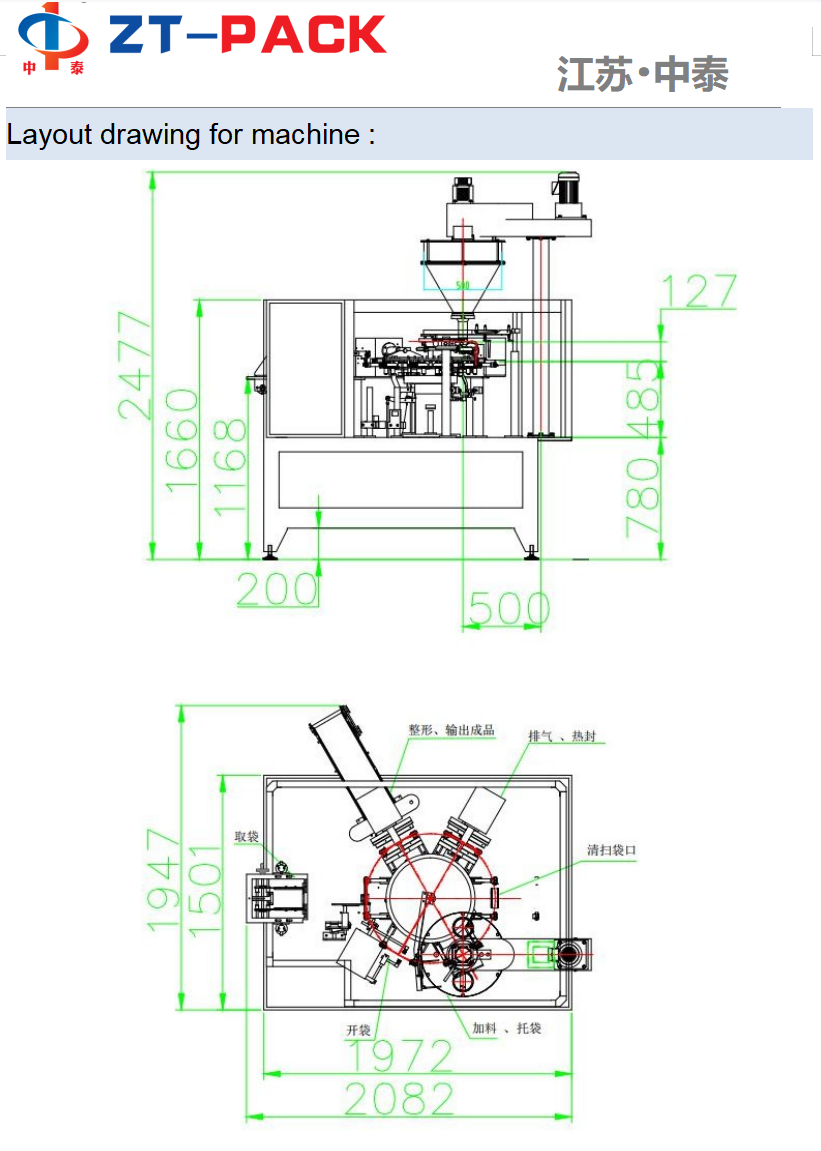

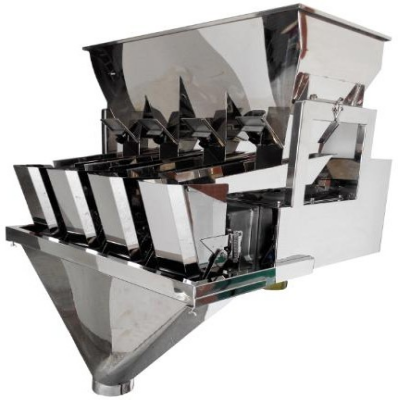

Machine Picture :

Machine Desprition :

This equipment is mainly from the bag to the automatic packaging machine and supporting the screw, for milk powder, coffee powder, condiments, additives and other powder materials, automatic measurement packaging machine.

Main Features and Characteristics:

A wide range of pouches:

all kinds of pre-made pouches such as flat and stand-up pouches (with/ without zip).

High speed: More than 20-35bags/min

Easy to operate: PLC controller and color touch-screen, fault indication on the touch screen.

Easy to adjust: only about 10 minutes to change different pouches.

Frequency control: speed can be adjusted by frequency conversion within the range.

High Automation: unmanned in weighing and packing process, machine alarm automatically when failure.

Waterproof design: the machine surface can be washed down, so easy cleaning, and

longer useful life.Dust & Water Proof:IP65 For Motors IP65 The machine can be scrubbed by wet cloth

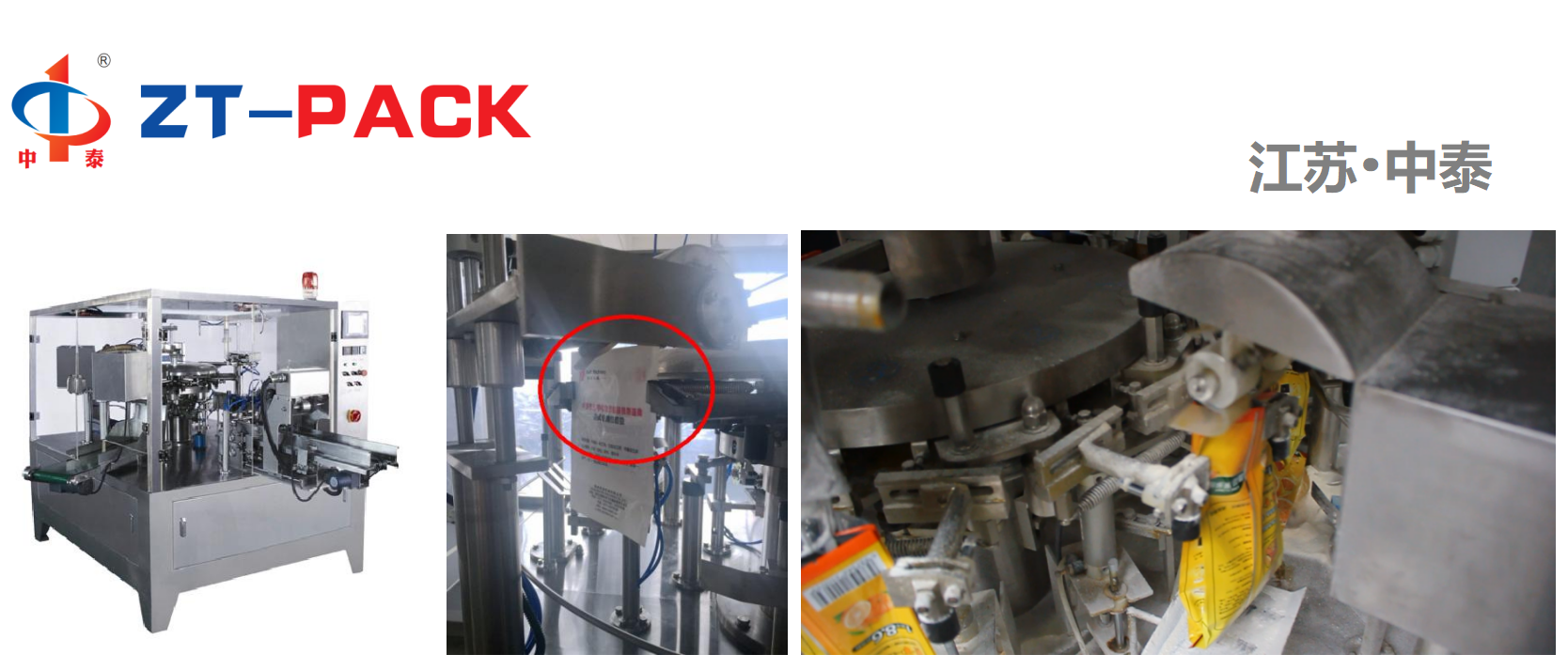

Details pictures :

Packaging Process:

Station 1 Bag dispensing (Bag feeding)

Feed many pouches or bags in the bag magazine, which can move up and down, and you can feed bags very easily when it moves down, and when it moves up, there are a mechanical arm with two vacuum caps will take bag up and then transmit it to the mechanical gripper on the rotary table.

Station 2 Coding (Date Printing)

Ribbon printer, Ink-jet printer for optional

Station 3 Bag Opening

Using air to open the bag, and an opening detection device inserts into the

opened bag to expanding it and detect if it is open or not.

Station 4 Filling

There are an opening detection device insert into the open bag or pouch to expanding it and detect

if it is open or not.

No open no filling no sealing

Station 5 Dust Clean

Clean the dust on the bag mouth for better heat sealing

Station 6 Heat sealing 1

To seal the bag with a couple of heat sealing air bar

Station 7 Heat sealing 2

Second sealing for sealing stronger

Station 8 Forming and product output

To make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished production automatically. (the sealing pattern with net or straight lines for your option)

For Granulate :

For Powder :

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible

Contact Info

ADDRESS: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Questions? Contact Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible