Machines

Packaging lines

Contact us

Cindy

Fiona

Tel:0086-136 8527 0809

E-mail:fiona@ztpack.net

Add: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Robert Palletilizer

Robotic type palletilizer for finished product and cartons

Product Description

The robot palletizer can be used in many production line, providing intelligent, mechanization for production site. It is a palletising logistic system which can be used in the industries of beer, water, soft drink, milk, beverage and foodstuff etc. It is widely used for carton, plastic crate, bottle, bag, barrel, shrink wrapped product and can etc.

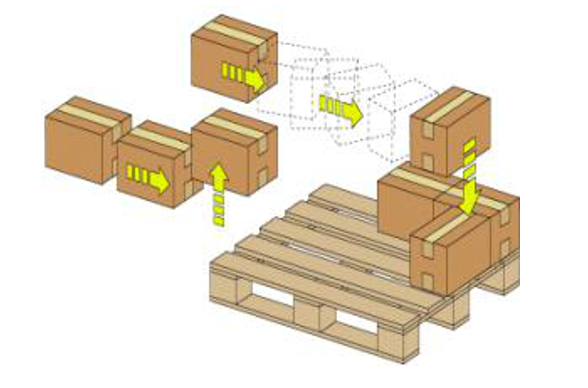

Workstation workflow

Preparation → Palletizing mode setting → Palletizing A → Palletizing B → Complete

|

Specification |

|

|

Maximum stacking height* |

The maximum stacking height of the lifting machine is 2100mm (including pallet); generally up to 1600mm (including pallet) |

|

Maximum pallet size* |

1200mm×1200mm (customized) |

|

Stackable box size* |

L (260-600) mm*W (200-600) mm*H (150-500) mm |

|

Maximum permissible load |

45kg |

|

Maximum stacking speed |

Up to 6 boxes per minute |

|

Working radius |

Maximum working radius 1700mm |

|

Safety features |

Optional: safety grating, safety fence, safety sensor carpet |

|

IP rating |

Robot arm IP54, gripper and other accessories are all IP32-compliant |

|

Interface |

Supports multiple safety inputs and outputs, including emergency stop, safety protection, administrator mode, factory setting mode |

|

Safety features |

Emergency stop function, reserved external safety interface (can be controlled through I/O interface) |

|

Indicator status |

When powered on normally, the indicator light is always green; when powered off, the indicator light is off |

|

*Maximum stack height refers to the use of the arm in a single box stack in the vicinity Using the maximum pallet size (1200mm×1200mm), it can generally reach 1600mm. The size of the box and the placement and gripper may affect the actual stack height *The maximum load of the robot arm itself is 45kg |

|

|

Product Composition |

|

|

Main components

|

Collaborative robot |

|

|

Operation and control system |

|

Electronic control components

|

Teach pendant and cables |

|

|

WSC collaborative robot V4 control system software package |

|

Frame components

End effector |

Convenient mobile fixed base |

|

|

Seventh axis lifting column module and drag chain |

|

|

Pallet detection sensor and indicator light |

|

Main components |

Jig, suction cup |

|

|

Pneumatic group: air treatment group, solenoid valve, air pipe at the end of the tool |

Next

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible

Contact Info

ADDRESS: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Questions? Contact Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible