Machines

Packaging lines

Contact us

Cindy

Fiona

Tel:0086-136 8527 0809

E-mail:fiona@ztpack.net

Add: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Automatic Rotor Pump Filling Machine

Suitable for : Yogurt food with Chunk and without , high viscous paste cream pump filling machines are best suited for filling viscous products, but they can be used to fill thin products as well. These fillers can handle a wide range of container sizes, fill volumes, and product types; but they are most ideal for filling pastes, creams, lotions, and gels, in large volumes and at greater speeds than otherwise achieved with a piston filler. Suitable For Viscous Food Standard Liquids Filling Can meet CIP System Requirements For Food Packing, It Is Ideal For Ketchup , Jam Sauce ect... with Chunk/granulate or without

Product Description

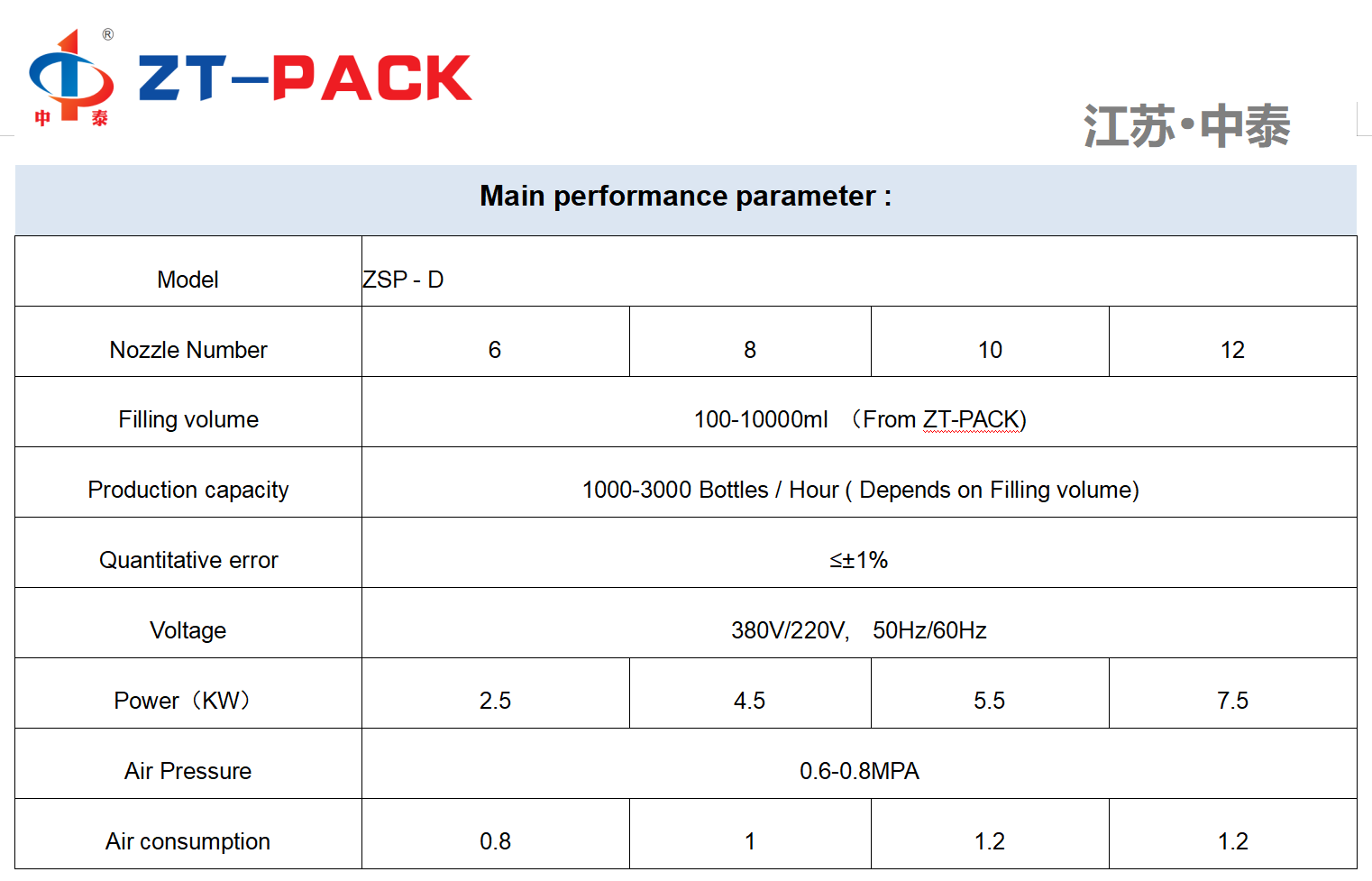

Machine Name : Automatic Yogurt Rotor Pump Filling Machine

Type: ZSP-D

Brief Introduce :

This filling machine is Cam rotor pump filling machine which is made for filling high viscous product and non-flowable paste such as mayonnaise, sealant ,grease etc.

The machine is made by Linear structure , filling head quantity can be custom-made according to different production capacity such as 6/8 heads.

The filling system is driven by servo motor which assure high filling accuracy ,also easy to set filling volume on the touch screen directly.

It is widely used in the cosmetic, foodstuff, specialty chemical, pharmaceutical, and personal care industries.

Suitable For Filling :

GMP clean Products , Food Sauce , Yogurt , Mayonnaise , Garlic Sauce ...

High paste , with and without chunk

Charactors :

1: NO PISTON , All parts can be clean well

2: Suitable for : with Chunk and without , high viscous paste cream

3: No filling size limited

4: Each one Filling nozzles with one set servo motor and servo driver control Cam Rotor Pump to make sure for high viscous and with chunk also high accuracy

5: From storage tank to filling machine tank included on the top , there is a infeed valve , transfer the material by pump ,filling tank to filling nozzles directly control by servo motors and Rotor pumps ,every filling nozzle with one set to control

6: Filling Machine tank is special made food grade level with clean function , can meet CIP station requirements for food clean

7: With Program for Machine Cleaning

8: Machine Material : All contact parts made of SUS 316L ; Machine Body made of SUS 304

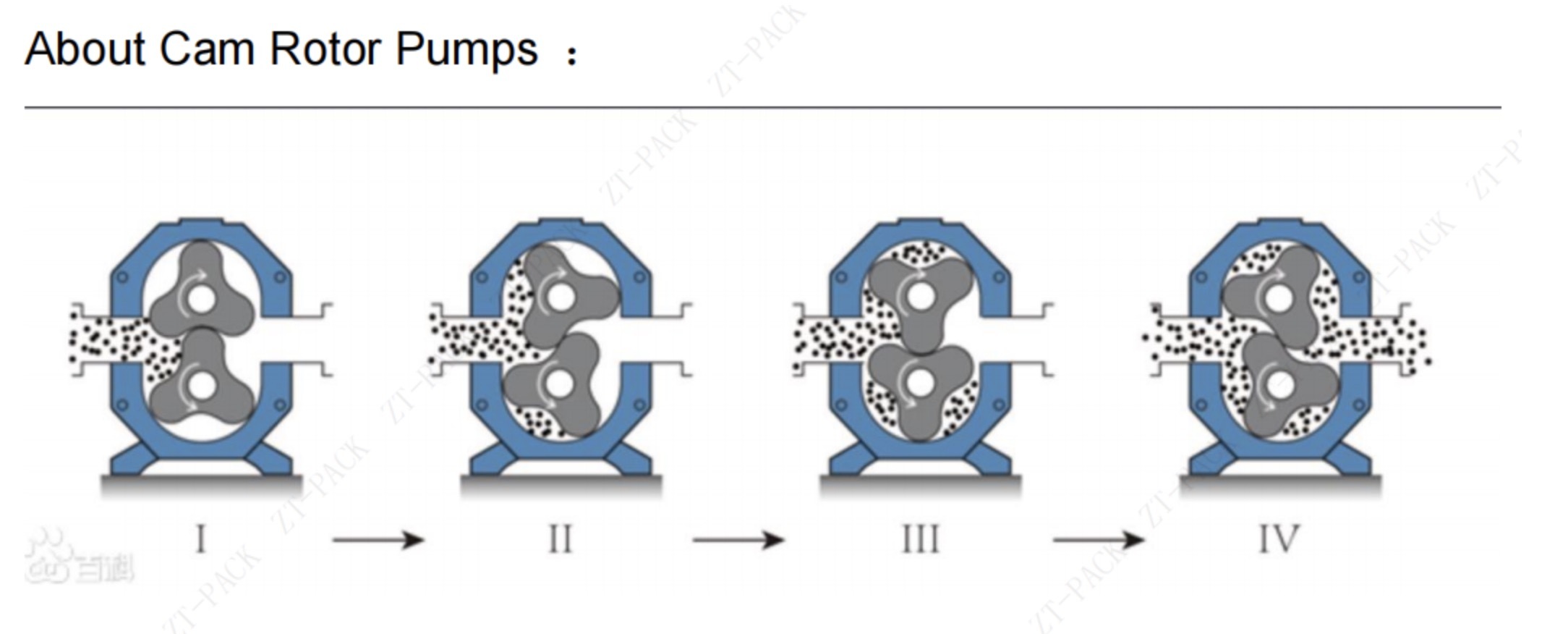

About Pumps :

Like gear pumps, lobe pumps are a type of positive displacement pump that uses a rotary action to move product.

Unlike gear pumps, a lobe pump will normally consist of about three lobes (versus the many teeth on the gear pump).

Product is pushed throught the lobes in a manner similar to passing through the teeth of a gear pump.

However, the extra space can be a benefit for products with small to medium particulates that may cause problems when passing through gears.

No filling range limited by traditional pistons

Ideal for food use especially with chunks granulates fruits

Linear Lobe pump filling machinery is manufactured with a 304 stainless steel frame, It comes standard with PLC control and touch screen HMI ensuring reliable, repeatable control with minimal operator intervention, Precision bored, heavy- walled metering cylinders dispense product at accuracy up to +/- 0.2%, High-precision, servo motor driven screw movement faster and more precise than pneumatic system, food grade stainless steel and plastics for sanitary operations or use,anodized aluminum components, plus many more features available with motorized conveyor and indexing package for integrated container handling and positioning, No container/No fill feature detects missing or mispositioned containers to prevent waste and product spillage.

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

About us

Workshop :

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible

Contact Info

ADDRESS: No.16,He Shan Huan Road, Jintan District, Changzhou City, Jiangsu Province,P.R. China

Questions? Contact Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible